Threadability Ltd.

The thread is the least understood aspect of metal machining and cutting the thread is usually one of the

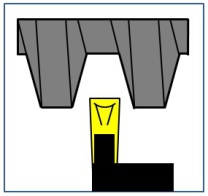

last machining operations in the production process. Why spend many expensive machine hours on the component then spoil it with a sub-standard thread? Full-form thread cutting

generates very large cutting forces which can lead to instability, resulting in poor surface finish and dimensional inaccuracy. Generating the thread profile reduces these cutting forces

significantly, giving you back control of the thread cutting! Now large threads are easy to produce - even on small machines.

Whether your thread is vee-form, trapezoidal, buttress, round or square, has chamfers or radii at the crests, is left or right-hand,

internal or external, parallel or tapered, single or multi-start, Threadability Ltd. has the solution to produce perfect threads in a controlled manner, usually with standard, off-the shelf

tooling.

With over 50 years in the metal-cutting industry, at Threadability Ltd., we focus on the CNC programming of threads that are either

beyond the cutting tool manufacturers’ standard threading tooling and software ranges, or, due to other constraints, not feasible to produce them with standard tooling and resident CNC canned

threading cycles or too urgent to be able to wait for custom-made threading tooling. We offer a reliable, quick-response CNC thread profile generating part-programming service with full

on-site support when required, with no affiliation to any particular cutting tool manufacturer.

Thread profile generation is applicable to the sub-sea, oilfield, pump, aerospace, nuclear, power generation, valve and general

engineering industries and all their related materials.